Safety is

Leadership & Employees

Our Leadership & Employees take an active part in enforcing accountability for all aspects of Safety and Health practices, while performing his/her duties.

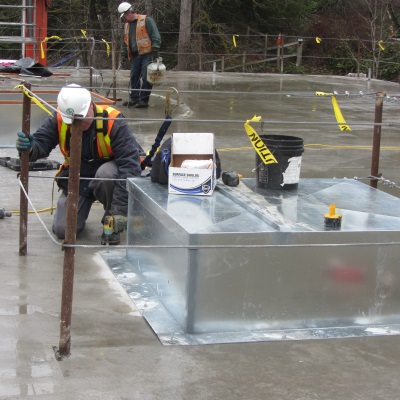

Worksite Analysis

In addition to daily worksite inspections, JMI arranges for audits and worksite analysis reviews to ensure the implementation of existing safety & risk management policies.

Training & Education

JMI's Safety program begins with each new employee, with Orientation. Followed by ongoing safety training by means of weekly Toolbox Talks, Job Hazard Analysis (JHA) forms, Daily Reports, and Inspection Checklist to document concerns or changes on every project.

New Employee Orientation

OSHA 10 -30 hour Trained

Activity Hazard Analysis

A Written Safety Program

Trade or equipment specific safety training. *PPE Program included.

First Aid /CPR/AED/Blood Borne Pathogen

Alcohol and Substance Abuse Policy

Safety Program Management

Johansen Mechanical aspires to eliminate unsafe conditions and minimize the impact of hazardous situations, property damage and environmental threats by maintaining full compliance of Local, State, and Federal codes, laws and standards of safety.

The protection of the health and safety of our customers, employees, guests, the general public, and the environment is of paramount importance to both Leadership & Employees at JMI.

Safety training begins with OSHA 10-30 hour training provided via the Western Washington Sheet Metal JATC Apprenticeship program. However, on their first day, new, inexperienced, and/or returning hires are required to participate in JMI's Safety & Risk Management Orientation. This training course will teach employees to understand their role in the company's safety program.

To maintain recognition as a AGC Safety Team member, JMI has to pass an annual safety audit that consists of a detail review of our company's jobsite safety policies and procedures to ensure we meet today's industry safety standards. *An approved safety audit checklist has well over 200 criteria to qualify.

AGC Safety Team status is recognized by the Washington State Department of Labor and Industries and OSHA.